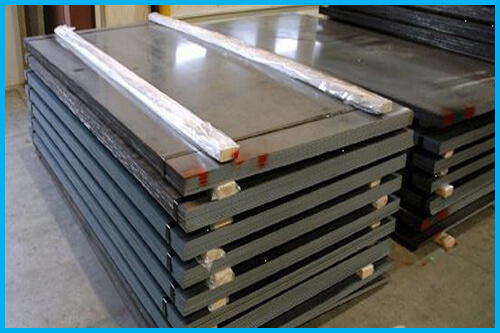

Wear Plates Suppliers

Introduction

Wear plates are engineered materials designed to withstand heavy abrasion and impact, thereby extending the life of machinery and reducing maintenance costs. They are commonly made from high-strength alloy steels and are utilized in environments where mechanical stress and wear are prevalent.Product Details

Wear plates come in various forms, including flat plates, liners, and custom shapes, depending on the application. Their primary function is to act as a protective barrier against wear caused by friction, impact, and corrosive environments. Vandan Steel & Engg. Co. specializes in manufacturing and supplying high-quality wear plates, ensuring they meet the specific needs of their clients across different sectors.Specifications

The specifications of wear plates can vary widely, but they typically include:- Material Composition: Often made from alloy steels, including carbon, chromium, and manganese, which enhance their wear resistance.

- Thickness: Available in various thicknesses to suit different applications, typically ranging from 6 mm to over 50 mm.

- Hardness: Measured on the Brinell or Rockwell scale, wear plates can have hardness ratings from 400 to 600 BHN, depending on the intended use.

- Dimensions: Custom sizes can be manufactured to fit specific machinery requirements.

Applications

Wear plates are utilized in numerous industries, including:- Construction: Used in heavy machinery like bulldozers and excavators to protect against abrasive materials.

- Mining: Essential for equipment such as draglines and shovels, where high wear resistance is crucial.

- Agriculture: Applied in farming equipment to enhance durability against soil and crop impacts.

- Energy: Utilized in power generation equipment to reduce wear from high-temperature and high-stress environments.

- Transportation: Found in vehicles and trailers, wear plates help minimize maintenance costs by protecting critical components from wear.

Implications on Industry

The use of wear plates has significant implications for various industries:- Cost Efficiency: By extending the lifespan of machinery, wear plates reduce the frequency of repairs and replacements, leading to lower operational costs.

- Increased Productivity: Enhanced durability of equipment allows for more continuous operation, minimizing downtime caused by maintenance.

- Safety: Protecting machinery from wear reduces the risk of equipment failure, thereby enhancing workplace safety.

- Sustainability: Longer-lasting equipment contributes to reduced waste and resource consumption, aligning with sustainable practices in manufacturing and industry.

.jpg)

Comments

Post a Comment